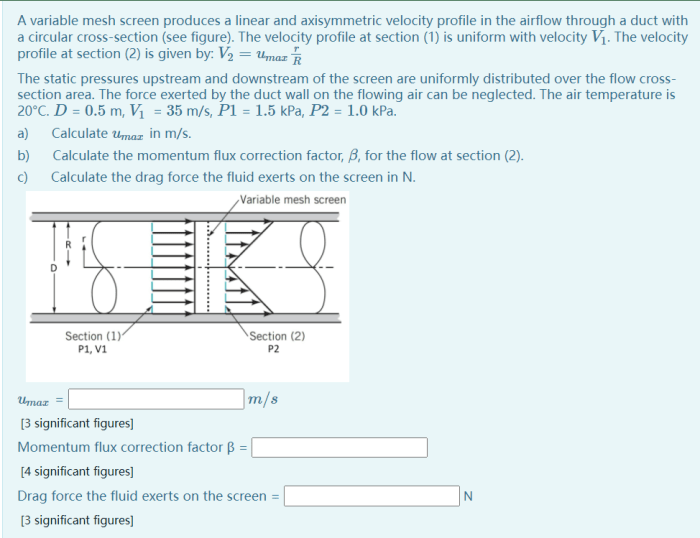

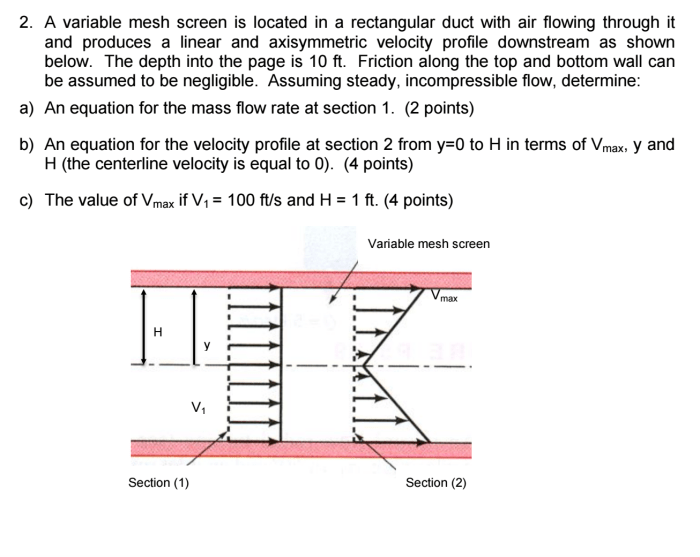

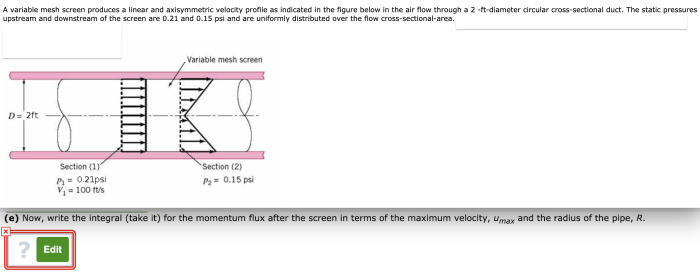

A variable mesh screen produces a linear and axisymmetric – In the realm of fluid dynamics, a variable mesh screen emerges as a transformative technology, offering unparalleled control over fluid flow characteristics. This innovative screen design paves the way for a wide array of applications, ranging from industrial processes to scientific research.

The unique construction of a variable mesh screen, characterized by its varying mesh density and pattern, profoundly influences fluid dynamics. It enables the precise manipulation of pressure drop, velocity distribution, and turbulence, unlocking new possibilities for fluid control.

Variable Mesh Screen: A Variable Mesh Screen Produces A Linear And Axisymmetric

A variable mesh screen is an innovative device that offers precise control over fluid flow dynamics. Its unique construction and design characteristics enable it to produce a linear and axisymmetric flow profile, making it a valuable tool in various industrial applications.

Mesh Structure, A variable mesh screen produces a linear and axisymmetric

A variable mesh screen consists of a series of perforated metal sheets arranged in a specific pattern. The density and pattern of the mesh vary along the length of the screen, creating a gradual change in the flow resistance.

Fluid Dynamics

The variable mesh screen influences fluid flow by altering the pressure drop, velocity distribution, and turbulence. As the fluid passes through the screen, the pressure drop increases gradually due to the varying mesh density. This results in a linear pressure drop along the length of the screen.

The mesh also affects the velocity distribution, creating a more uniform flow profile. The varying mesh density causes the fluid to accelerate and decelerate as it passes through the screen, reducing turbulence and promoting a stable flow.

Linearity and Axisymmetry

Linearity refers to the constant pressure drop along the length of the variable mesh screen. This characteristic ensures a predictable and controlled flow rate, making it ideal for applications requiring precise fluid metering.

Axisymmetry refers to the symmetrical flow pattern around the central axis of the screen. This property ensures that the flow is evenly distributed and free from any directional bias, resulting in a stable and uniform flow profile.

Applications

Variable mesh screens are used in a wide range of applications, including:

- Flow metering and control

- Gas and liquid filtration

- Pressure regulation

- Acoustic damping

- Heat exchangers

Design Considerations

When designing a variable mesh screen, several key parameters must be considered:

- Mesh density

- Screen thickness

- Flow rate

- Pressure drop requirements

Manufacturing Techniques

Variable mesh screens are manufactured using various techniques, including:

- Laser cutting

- Waterjet cutting

- Chemical etching

Each method offers advantages and disadvantages in terms of precision, cost, and material compatibility.

Top FAQs

What are the key advantages of using a variable mesh screen?

Variable mesh screens offer numerous advantages, including precise control over pressure drop, enhanced flow uniformity, and reduced turbulence. These benefits translate into improved performance and efficiency in various applications.

How does a variable mesh screen achieve linearity in flow?

The varying mesh density along the length of the screen generates a gradual pressure drop, resulting in a linear pressure profile. This linearity ensures consistent flow characteristics throughout the screen.

What is the significance of axisymmetry in a variable mesh screen?

Axisymmetry in a variable mesh screen implies that the flow pattern and pressure distribution remain symmetrical around the central axis. This characteristic simplifies fluid dynamics analysis and enables precise control over flow behavior.