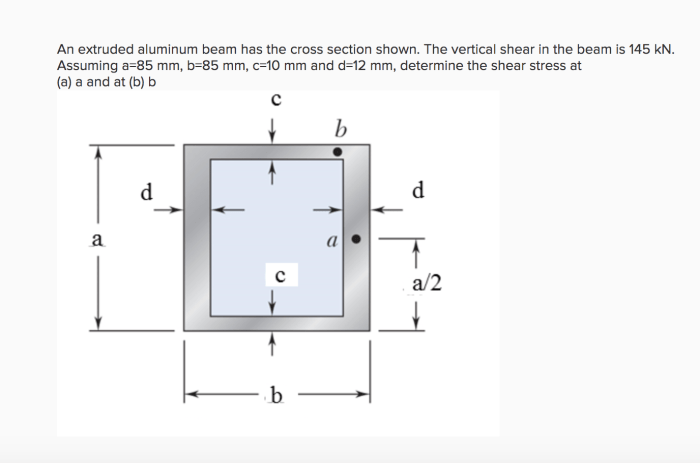

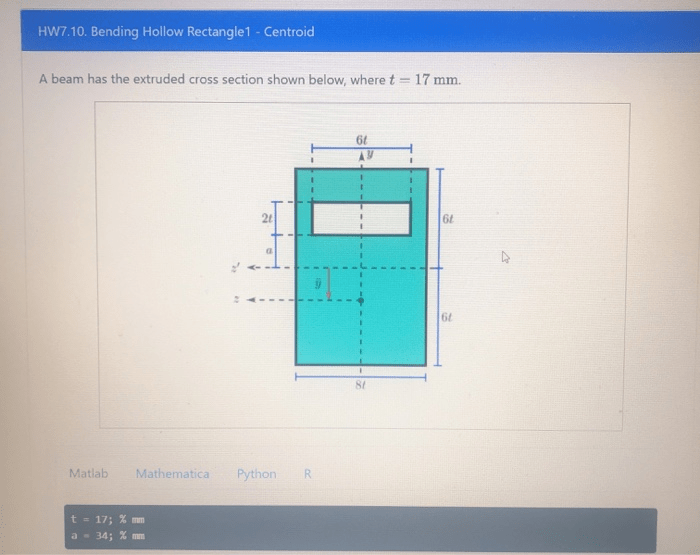

A beam has the extruded cross section shown below where structural engineers and architects collaborate to create innovative and efficient structures. This article explores the intricate world of extruded cross-section beams, delving into their structural analysis, material properties, loading conditions, and real-world applications.

Extruded cross-section beams possess unique geometric profiles that enhance their structural performance, making them ideal for various engineering applications. Their optimized shapes allow for efficient load distribution, reducing material usage and minimizing overall weight.

Extruded Cross-Section Beam

An extruded cross-section beam is a structural element with a profile that is formed by forcing a heated metal alloy through a shaped die. This process results in a continuous, uniform cross-section along the length of the beam.

The given extruded cross-section is characterized by a hollow, rectangular shape with rounded corners. The walls of the rectangle are of uniform thickness, and the overall dimensions and proportions of the cross-section can be tailored to meet specific design requirements.

Structural Analysis

The structural behavior of a beam with an extruded cross-section can be analyzed using various methods, including:

- Finite element analysis (FEA):A numerical technique that divides the beam into small elements and solves the governing equations for each element to determine the overall behavior of the beam.

- Hand calculations:Simplified analytical methods that use closed-form equations to approximate the beam’s response to loading.

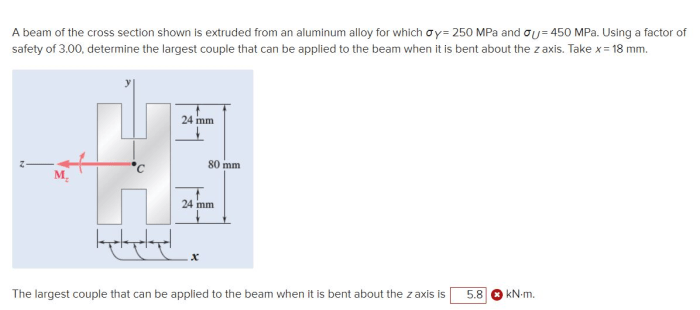

Material Properties

Extruded cross-section beams are typically constructed from aluminum alloys, steel, or composites. The choice of material depends on the desired properties of the beam, such as strength, stiffness, weight, and corrosion resistance.

The material properties of the beam, such as its modulus of elasticity and yield strength, influence its behavior under load. Higher modulus of elasticity indicates greater stiffness, while higher yield strength indicates greater resistance to permanent deformation.

Loading Conditions

A beam with an extruded cross-section can be subjected to various loading conditions, including:

- Static loading:Constant or gradually applied loads that do not vary significantly over time.

- Dynamic loading:Time-varying loads that can cause vibrations or impact forces.

- Fatigue loading:Repeated or cyclic loads that can lead to material failure over time.

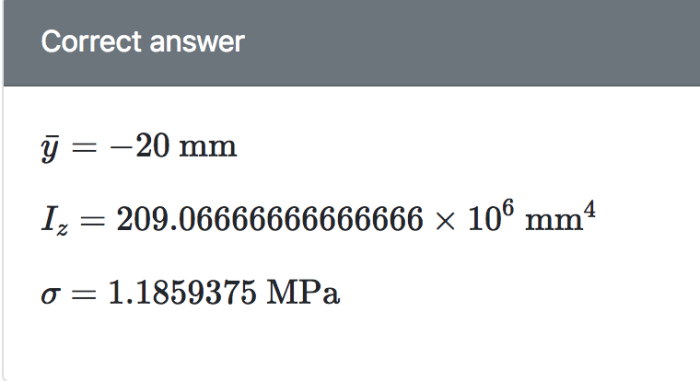

Stress and Strain Analysis

Stress and strain are measures of the internal forces and deformations within a beam under load. Stress is defined as the force per unit area acting on the beam, while strain is defined as the deformation per unit length.

For a beam with an extruded cross-section, the stress and strain distribution can be calculated using analytical or numerical methods. These calculations are essential for assessing the beam’s structural integrity and predicting its behavior under various loading conditions.

Design Considerations

When designing a beam with an extruded cross-section, several factors must be considered, including:

- Strength:The beam must be strong enough to withstand the applied loads without failure.

- Stiffness:The beam must be stiff enough to minimize deflections under load.

- Weight:The beam should be as light as possible without compromising strength or stiffness.

Applications, A beam has the extruded cross section shown below where

Beams with extruded cross-sections are commonly used in various applications, including:

- Automotive industry:Structural components, such as chassis and suspension systems.

- Aerospace industry:Lightweight and high-strength components, such as aircraft wings and fuselage frames.

- Construction industry:Structural supports, such as beams and columns in buildings and bridges.

Detailed FAQs: A Beam Has The Extruded Cross Section Shown Below Where

What are the advantages of using extruded cross-section beams?

Extruded cross-section beams offer several advantages, including enhanced structural performance, reduced material usage, and optimized weight distribution.

How are extruded cross-section beams analyzed structurally?

Structural analysis of extruded cross-section beams involves employing analytical techniques such as finite element analysis or hand calculations to determine their behavior under various loading conditions.

What types of materials are commonly used in extruded cross-section beams?

Common materials used in extruded cross-section beams include steel, aluminum, and composite materials, each offering unique properties to suit specific applications.